Further explanation of why the F-35 is militarily useless.

There are two previous posts.

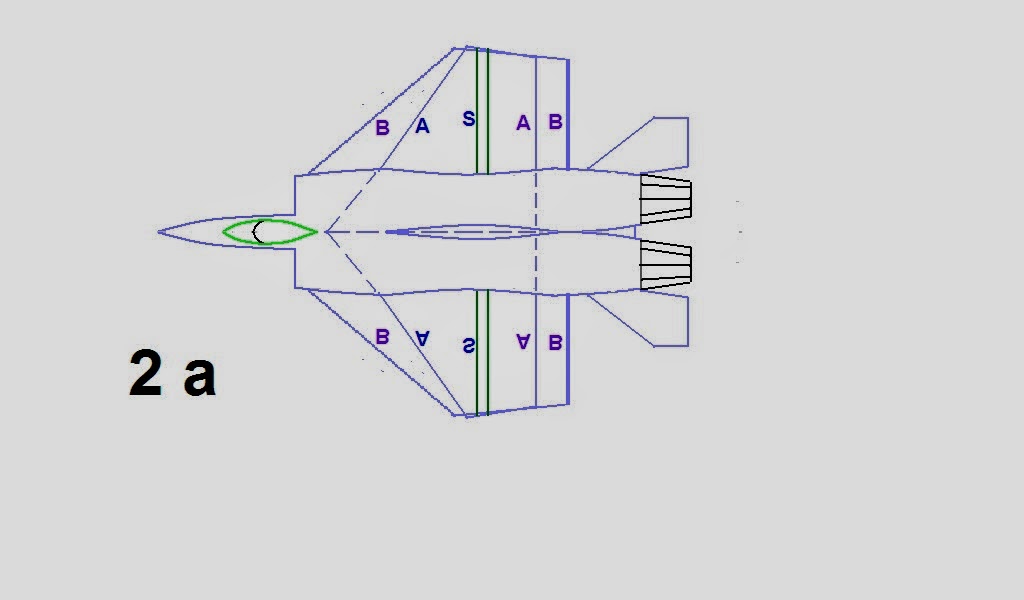

The Reynold's number measures the separation of flow. A method to reduce the separation of flow form the wing is to reduce the thickness to cord ratio, the greatest thickness, top to bottom measurement of a wing divided by the cord, front to back edge measurement. For structural considerations, the wing depth is measured from the center of the top wing skin to the center of the bottom wing skin. If this depth is A and one half the top thickness plus one half the bottom thickness is B the outer, aerodynamic, thickness is A+B. If the depth is doubled but the thickness is halved the outer depth is 2A+1/2B. If that is divided by twice the cord the wing is aerodynamically thinner, lower thickness to cord. That would improve high-speed flight. As explained previously, a further thinning might be achieved to improve aerodynamics.

Incompressible flow likes straight wings, compressible flow prefers highly swept wings. Normally, the wing has to be compromised to allow for both flows. By separating the aircraft into two parts an optimal wing can be chosen for both flows. This means that the combination aircraft can be designed for short take-offs, 1200=1500 foot runways instead of 3500 foot runways. In addition the wing profile, cross sectional shape, of the fighter can be chosen entirely for high speed flow, ignoring low speed flows, and possibly providing some additional aerodynamic improvement.

Stability and control are the other serious considerations. One definition of designing aircraft is choosing which instabilities on can live with and then designing the aircraft around them. Under subsonic flow the aerodynamic center(a-c), the average point of lift is located at eh 1/4 cord point, 1/4 of the distance from the front to the trailing edge of the wing. Under supersonic flight the a-c is at 1/2 cord, the longer the cord the greater the shift and the more compensation required.

Attempts to build separable aircraft tended to fail because they placed the separating aircraft on top of the carrier aircraft, this raised the center of mass making the two aircraft set less stable and required extreme care at separation to avoid collisions. Hanging the aircraft underneath and extending it on a boom before separation solves both problems.

Operationally, a two part aircraft requires a higher workload. Once the fighter has separated the lifting wing must either land, and then take-off again to recover the fighter, or fly around in circles taking up air space and burning fuel until the fighter returns. Landing means twice as many aircraft movements form the airfield and circling leaves the wing vulnerable to being shot down. If the fighter is going to land at a different field, the wings could be sent by a different route as long as the flight times are comparable, if the fighter has a one hour mission , the wing can fly one hour, 500 miles to another field for recovery. For long range transfers, the fighter could fly on the extended boom as a two aircraft formation. There would be a need to have extra wings for contingencies. It should be possible to transfer fuel down the boom, allowing the wing to be used as a robotic tanker. The other potential use for the wing would be as a cruise missile bus, loaded with cruise missiles and fuel it could fly forward and release them.

For carrier operations, ideally, the wing would be vertical landing. This would obviate the need for arresting wires and a landing strip, allowing the carrier to be divided into three zones; a rear landing zone, a middle aircraft handling zone and a forward catapult launching zone. There should be two landing zones, one left and one right across the deck. This would allow for simultaneous landings and, combined with the ability to launch and recover at the same time allow for a higher tempo of aircraft operations. To have two landing zones the deck would probably have to be at least 300 feet wide. That would require a hull 200 feet wide. Aircraft carriers are built as 6:1 ships, 6 times as long as wide, that means the the hulls of carriers should be 1200 feet long. They are currently about 1080 feet. There is a carrier named

Reagan, since Reagan bought the wrong and obsolete aircraft as well as miss-designed under-sized carriers, it is a fitting, although ironic, fact that he should have one of those miss-designed carriers named after him as a monument to his own incompetence. There is no need to worry about replacing the carriers, they only cost $8 billion.

For catapult launches, there may have to be two catapult tracks for each launch, owing to the duel forward landing gear, attaching only one to a catapult would drag the aircraft down the deck crabwise. A second track, attached to the other gear, which would be a non-active catapult, would allow for a cleaner take-off.

AWACS aircraft would have to also be vertical landing to remove the use of arrestor wires. The radome would be placed under the aircraft to lower height and allow for placing onto the hanger deck.

The main advantage for a two part aircraft for carrier operations is that the fighter would be identical to an air force fighter. Currently, air force fighter use an aspect ratio of 2.5 and naval fighters use an aspect ratio of 4 to allow for lower landing speeds. The higher aspect ratio means a heavier wing wich is less efficient in high speed flight.

When the fighter is under the wing, it would be best to have the cockpit in front of the engine intakes for the wing, allowing the pilot to eject. The danger comes when the pilot is attached by the boom when extended, as the pilot would have to separate and disentangle from the connection before ejecting.

One question, would be when and how to eject water form the pilot's suit during the ejection sequence. Compressed air could be blown in and a relief valve would allow purging. The pilot would probably wear something like an olympic swim suit next to his skin.This would men the pilot would have to eject with a clothing bundle to dress for evasion and escape.

The flight controls could actually be contained in pressure sensitive gloves. The pilot's arm could be on an arm rest while his hand would be around a neutral object, a post. For control, the pilot would press his hand against the post , the squeezing of the glove between hand and post would register as a control signal. The pilot would be able to use finger-tip pressure pads to "type" in instructions as well as possible voice activation.

For the survival snorkle, it would be 3 inches tall but the water pressure would collapse the diaphram under 2 inches of water preventing water ingestion and aspiration. At the narrow ends of the snorkle, a teardrop shaped post would be insine the diaphragm with the diaphram trapped between the post and structural tube.

The pointed inner edge of the post might have ogive curves to provide a better seal when the diaphram closes. The diaphram itself would have ridges or waves in vertical cross-section to provide a better seal when closed. The snorkle would be attached to the hood with effectively, a large rubber band.

For pilots in the ocean, a rescue submersible, 10, could be deployed from a C-130 or a C-17. A three man crew would be seated facing backwards on crash resistant seats, 10a. The entire craft would be slowed by parachutes and, additionally, rockeet motors to slow the descent. After entry into the water, one crew member would enter the forward driver area while the remaining two would remain in the rear shelter area. For the rescue, a side door would be opened and a resue swimmer would pull the pilot alongside and then both crew would pull hi inside assisted by a winch if necessary. They would stabilize the pilot and await rescue.

The vehicle would be 16-20 feet long, 8-10 feet wide and 8 feet tall overall. It would weigh 10 000- 20 000 lbs. It would be made out of aluminum armor plate and have a heavy windshield. A flotation ring could be inflated for additional buoyancy after water entry. Its engine would use a liquid mono-propellant for long term storage and to prevent the engine being drowned. It would have a hatch in its roof to allow helicopter evacuation of personnel. It could also be lifted by a crane onto a ship's deck.

For the rescue, The pilot would have a strobe light and the vehicle would have a strobe, the airccraft after deploying would circle directing one strobe onto the other.

Unfortunately, back in the 1960s, there was a TV show called

The Thunderbirds, it used marionettes for characters, a pOf all teh goofy nonsense produced for militarrocess the creator called "super-marionettization", a scientist had his secret location and used rockets and submersibles for daring missions. One of those craft, labelled Thunderbird 1, Thunderbird 2, etc., I think, looked something like this. Sorry.

The separation of a fighter into two parts would have given a significant improvement in performance as soon as fighters hit 600 mph, that was 1950. For all the goofy nonsense produced for military aviation during the 1950s, such as prototypes of a super-sonic seaplane fighter, a two piece aircraft was never tested, even though it would have greatly improved performance.

There were some test flights with a plane called the McDonnell XF-85 Goblin which was intended to be carried in the bomb bay of the B-36 bomber and flew off of a trapeze and had no landing gear. It was intended to allow fighters to be available for bombers and was not done to improve overall fighter performance.

The problem at that time was that there was no way to automatically join the aircraft, two additional crew members would have been needed to fly the wing, one to pilot, the other to work the boom. It still would have been worth testing. By 1968, in Vietnam, laser guided bombs became available. They required two planes, F-4s, one dropped the bomb, in dive-bombing, the other flew a baked turn with a pilot in the back seat shining a laser pointer through the side canopy. Lasers are the most obvious way for the connection to be accomplished.

I will be generous and say 1975 was when a test aircraft could have been built. That was Donald Rumsfeld's first time as Secretary of Defense. It was the Ford administration, telephones had wires and music was produced from twelve inch plastic discs, it was a long time ago. Every fighter produced since then, F-15, F-16, F-18, F-22, F-35, Typhoon, Tornado, Rafale, Grippen, Su-27, Su37, Mig-29, were all obsolete, it is the biggest procurement failure in military history. The entire Reagan defense build-up was a complete waste of money, they only bought obsolete garbage. All of the secretaries of defense, air force and navy have been negligent along with the president and both houses of congress, especially the armed services committees and their members and staffs. And no one will ever be held accountable.

I wrote to DARPA in 2010, they said they do not take suggestions. These re the idiots who actually publicly announced that they gave money to study helicopter Humvee. That will not work, the rotor dynamics say that for 10 lbs disc loading, weight divided by the circular area swept by rotors, 90 fps thrust would be produced, that must be multiplied by 4/3 to account for inefficiencies for a flow of 120 fps. One horse-power is 550 ft-lbs/sec. They said 500 hp. 550X500/120= 2500lb total weight. A Humvee carries 1500 lbs. At 5 lb disc loading; 63 fps X4/3= 84fps. 550X500/84 = 3300 lbs. In a few minutes, Icould tell them it would not work, but they do not ask me. The requirements for working at DARPA are having too much degree and not enough ability. If you have a Ph.D. but are not actually very good at engineering, a DARPA career could be in your future.

This entire design is a third year engineering problem, not even graduate level, separating a problem into two parts and solving each individually is a standard technique in mathematics and engineering.

I also wrote to the air force and they ignored me. I guess i should have tried the Russian and Chinese embassies, since the U.S. does not want to modernize, maybe they would. There is no point in contacting congress, all the members, and all their staffs are useless. There is a wall of psychosis around the government and it cannot be breached. They have lost at least a year of development and any other nation that wishes can enter the race for the 12g fighter, if anyone ever reads this blog.

To discuss high altitude flight we must discuss engines.

To discuss high altitude flight we must discuss engines.