In a number of cities, San Francisco, Stockholm and others buses are powered by overhead electric lines, sometimes called trolley buses. The wire itself is called trolley wire in the trade. The wire comes in pure copper and bronze alloys containing 80%, 60% or 40% copper, the remainder being mostly tin.

In order to replace gasoline trolley wire could be stretched over major roads to allow vehicles to not only use the power for propulsion , but also to simultaneously recharge their batteries. A vehicle would drive on batteries to the wire, run under power while recharging the batteries and then drive off the wire under battery power to a final destination.

There are about 400 000 miles of highway in the U.S, allow 5 lanes of highway, most highways by length have only four lanes, two in each direction. That is a total of 2 000 000 lane miles. For populous areas, there are about 300 000 000 people in the U.S. Assume 15 000 people per square mile for a total of 20 000 square miles. Allow to streets east-west and two streets north-south to be electrified for each square mile. Allow two lanes in each direction for a total of four lanes or a total of 320 000 lane miles. In many areas the highways are not close enough so county raods are needed for transit, guess 700 000 lane miles for a total of 3 000 000 lane miles electrified.

For rural areas, there is room to install the supports and wires, so, it is relatively easy work, A foundation and post must be installed on either side of the roadway to support the frame over the roadway. Say five men working ten hours for each side. Actually the foundation boring team, concrete pouring team and steel erecting team would be different groups but this is a rough estimate. That is 2X5X10= 100 man-hours. Say ten men working ten hours to erect the frame across the road, 10X10=100 man-hours. And again, ten men for ten hours to stretch the supporting cables and trolley wire, 10X10= 100 man-hours. All told, 300 man- hours per frame. Assume the frames are spaced every 150 feet, for a total of 35 per mile. 300 man-hoursX35= 10 000 man-hours per mile , at $100/man-hour, that includes wages, benefits, insurance and equipment being used, for a total of $1 000 000 per mile. This should be an overestimate. For two lanes, that is 1/2 million dollars per lane mile. There is the cost of trolley wire and steel as well as transformers and transmission lines, but I am being very loose with numbers.

Of the 3 000 000 lane miles to be electrified, take 2 000 000 as rural. At $1/2 million per lane-mile, it equals $1 trillion. For the additional 1 000 000 lane miles assume $2 million per lane mile to allow for the extra cost of building in built up areas, this is an even worse guess. That would be $2 trillion. The total is $3 trillion. Assume there are government loan guarantees and the total finance cost is 8% or $240 billion per year.

A gallon of gasoline has about 32 kilowatt-hours(kwh) of energy. The useful energy is about 9 kwh. For an electric motor to generate 9 kwh of work it must use additional total energy to evercome line losses and motor ineffiencies, that would be a total of 12-14kwh. However the battery recovers energy from motion, which is why a hybrid gets better mileage, so back to 8-9 kwh. About 160 billion gallons of gasoline are used each year plus 20 billion gallons of truck diesel, diesel has more energy and the motors are more efficient so a gallon of diesel produces about 15 kwh of work, but, just to simply total it, 180 billion gallons of fuel at 9 kwh per gallon equals 1.6 trillion kwh. For the $240 billion in finance costs that is 15 cents per kwh.

The numbers I have seen for electricity generation are 6 cents per kwh for coal, 8 cents for wind, but that can be much lower in some locales and 10 cents for nuclear. I will take the 10 cents and have nuclear powered cars. 10 cents lus 15 cents for the distribution network equals 25 cents per kwh, at 9 kwh per gallon equivalent equals $2.25 /gallon.

Billing for the usage is problematic so assume 20% of the electricity is stolen, that would increase the price by 25%, or a total of $2.80 /gallon. In addition the batteries wear out and their cost must further increment the price. Also, one must allow for theft, vandalism, damage and maintenance for the system. My point is that the costs are comparable and therefor worth further consideration. Building a wire network and using electricity might cost no more than using gasoline.

One of the great failings of the free market is its short-sighted stupidity. If thee is no electric network, gasoline prices would remain high, but if the electric network is built, gasoline prices fall undercutting the electric grid, causing it to go bankrupt and leading to higher gasoline prices. The numbers I have seen for tar sands and deep water oil are $60/ barrel(bl). There are 42 gallons in a barrel or about $1.50 per gallon, add another $!.00 for processing and distribution and there is a minimum sustained price of $2.50/gallon. The electricity might come close to that ignoring the battery cost.

With the electric highways, the distance a car would travel using batteries could be significantly reduced. Instead of fifty miles per day of battery usage, it might be less than five. With lower usage the batteries should last longer reducing the cost of their replacement. In addition smaller batteries could be fitted which would limit rural driving but would be less expensive to produce.

A line of trucks spaced every 100 feet, maximum trailer length is 53 feet in the U.S with a total truck length of 75 feet. Each truck is using 200 horsepower or 150 kilowatts(kw). Allowing 180 kw for losses is 180X50 /mile= 9 000 kw or 9 000 000 watts. If the voltage is 6 000 volts, 9 000 000/ 6 000 = 1500 amps. 5 000 lb /mile 40% trolley wire has the magic number of .4 amps/ mile line losses. 1 500 X .4 X 1/2 mile average length = 300 volts drop or 5% line drop, which is acceptable. 6 000 volts represents an electrocution hazard and could cause fires from contact with tree branches but it would allow transformers to be spaced every two miles. The other factor is current density. The wire is 0.24 in sq , so 1500 amps/ 0.24 in sq =

6 000 amps per square inch which may be excessive. It is unlikely to have that many trucks in a line, but for safety it might be necessary to fabricate extra heavy trolley wire.

One other shortfall is the shear dorkiness of the car with its pantograph up, it would take a hard-core geek to actually want to drive a car that looks like that, but money is money. The pantograph would be best to have a means for self retracting to avoid obstacle and to self raise when under wires, but that might not be easy. To allow for trucks, the pantograph would be 15-16 feet above the roadway. Oversize loads on trucks might be difficult to move, but most are under 15 feet tall.

The other question for cars is stability.

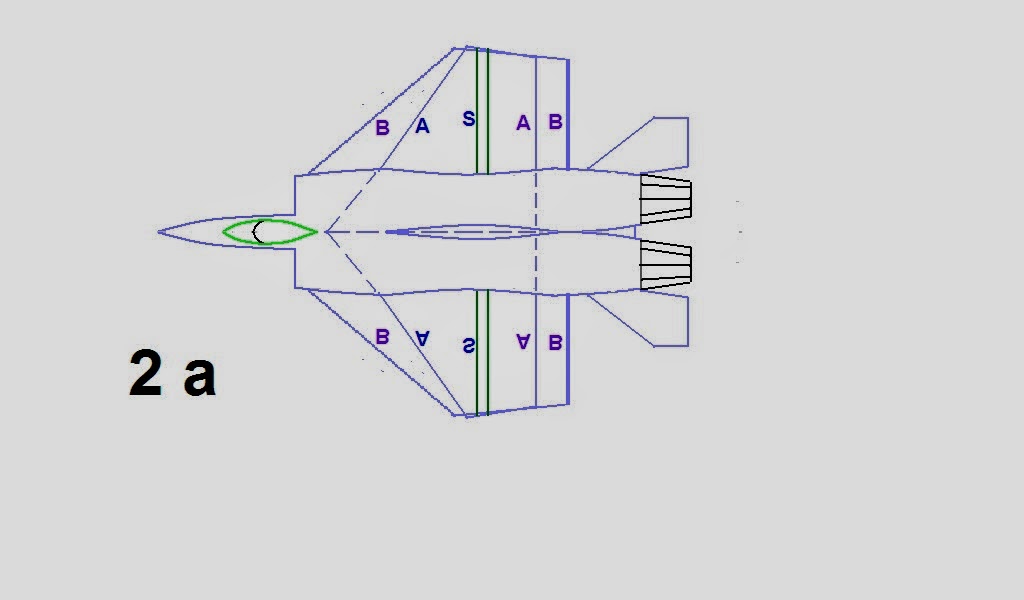

The drawing> shows both wind from front, just driving and forward wind of 60mph and side wind of 40 mph. In a, the round shape produces high drag in all directions. In b, a tear drop reduces drag from the front but increases it form the side. Since the pantograph is above the car the side wind will tend to overturn and destabilize the car. In c, flexible louvers, deflect the air in both motions and could reduce drag, but they might be broken. In d,air blown up the tubes forms streamlining flows that might adapt to both directions and minimize drag and overturning. The air is vented out holes in the tubes to form a boundary layer that deforms with the airflow minimizing drag.

^There is an enormous start-up cost, since the network of electric highways must be built before people will buy cars and, in the interim, there will be only limited revenue to offset costs.

I sent this as an electrified highway for trucks to the US Department of Energy, they ignored me.